top of page

Power-Assist Wheelchair Capstone Project

A device that quickly converts a manual wheelchair to a power-assisted one

DESCRIPTION

A device intended for a healthcare setting to reduce the load on wheelchair attendants that have to push patients all day long. It uses a quick-release 'claw' to grip the spokes of the wheel and apply a torque proportional to the attendants push

FEATURES

-

Quick installation

-

50% power assist on inclines

-

Drives by spokes

-

<10 lb.

-

Sleek design

-

Visible control indicators

-

Proportional power assist

-

Retains full wheelchair funciotnality

-

Reverse and overdrive safeguards

-

Emergency disengagement

-

No permanent hardware

-

Follows healthcare regulations

-

Full day battery

-

Modular design

-

Intuitive opperation

-

No interference with attendant or doorways

PROCESS

Problem Statement:

To create a rapidly-deployed device that reduces the force required to push a wheelchair in a healthcare setting.

Research:

-

Patent research: all expired

-

existing products: none in healthcare

-

Other uses of power-assist technology: skateboards, hover boards...

Ideation:

-

How can we reduce stress on nurse attendants?

-

Methods of applying power

-

Locations on the wheelchair

-

Combining existing ideas

-

Solving pain points of existing products

-

Focus on quick release and ease of use

Power Requirement:

-

Analytical calculations

-

Optimized variables

-

Confirmed in testing

Phase 1 CAD Design:

-

Simple block structure

-

Minimal features

-

For testing basic functionality

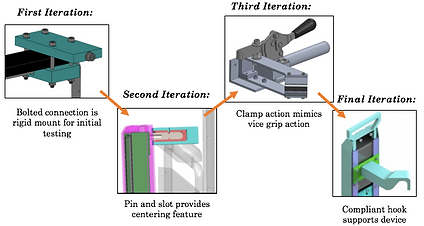

Iterative component design:

-

Armrest clamp Hook

-

Structural channel Plastic housing

-

Spoke clamps Spring loaded wedges

-

Basic drivetrain Flywheel and needle bearing

-

On/off Controls Added sensors and indicators

Component Analysis and Optimization:

Final Design

1st

place

-

Time and project management

-

Importance of backup plans

-

Turning concept into reality in short period of time

-

Sharing responsibilities within a leader-less team

-

Technical aspects of motor selection, drivetrain design, and controls

-

Optimizing designs with FEA

-

Presenting/selling ideas, progress, and reasonings

-

In depth market research

-

Machine shop practice

LEARNINGS

CHALLENGES

-

Tight timeline with many ongoing deliverables

-

Pivoting and overcoming continuous setbacks (regulations, market research, assembly issues, design oversights...)

-

Optimizing ease of installation and operation with functionality, cost, and timeline

-

Adding reverse and overdrive functionality

-

Accounting for tolerances between wheelchair dimensions

-

Control system for proportional power assist

-

Measuring value added/success

bottom of page